The Secret to a Durable and Long-Lasting Finish: Unleashing the Power of Primer Surfaces

When it comes to vinyl car wraps, a strong bond between the wrap and the surface is crucial for a durable and long-lasting finish. One of the most critical factors that can make or break this bond is the surface preparation, specifically the use of primer surfaces. But the question remains: will vinyl car wrap adhere to primer surfaces securely? In this article, we’ll delve into the world of vinyl car wrap adhesion and explore the importance of surface preparation, the science behind adhesion, and expert tips for ensuring a secure bond between your vinyl car wrap and primer surface. By the end of this article, you’ll have a comprehensive understanding of how to achieve a strong and durable bond that will make your vinyl car wrap look amazing and last for years to come.

The importance of surface preparation cannot be overstated. A well-prepared surface is essential for a successful vinyl car wrap installation. This is where primer surfaces come in. By applying a primer to the surface, you can create a smooth, even, and clean surface that allows the vinyl car wrap to adhere securely. But what exactly makes primer surfaces so effective? And how do they interact with the adhesives used in vinyl car wraps?

In the following sections, we’ll explore the role of primer in surface preparation, the science behind vinyl car wrap adhesion, and expert tips for ensuring a secure bond. Whether you’re a seasoned vinyl car wrap installer or just starting out, this article will provide you with the knowledge and insights you need to take your vinyl car wrap installations to the next level.

1. The Importance of Surface Preparation for Vinyl Car Wraps

Surface preparation is the foundation of a successful vinyl car wrap installation. A well-prepared surface is essential for a strong and durable bond between the wrap and the car. Neglecting this critical step can lead to a poor installation, peeling, and even damage to the car’s paint. On the other hand, a well-prepared surface ensures a smooth, even, and long-lasting finish. So, why is surface preparation so crucial?

A clean and smooth surface allows the adhesive to bond effectively, creating a watertight seal that prevents air and moisture from getting trapped under the wrap. This, in turn, prevents bubbles, wrinkles, and peeling. Moreover, a well-prepared surface ensures that the wrap conforms to the car’s contours, creating a seamless and professional-looking finish. By taking the time to prepare the surface, you can avoid common installation mistakes, reduce downtime, and increase customer satisfaction.

In the following sections, we’ll dive deeper into the role of primer in surface preparation and explore the common surface imperfections that can compromise the adhesion of your vinyl car wrap. Whether you’re a seasoned installer or just starting out, understanding the importance of surface preparation will help you achieve a superior finish and take your vinyl car wrap installations to the next level.

The Role of Primer in Surface Preparation

When it comes to surface preparation, primer plays a crucial role in ensuring a strong and durable bond between the vinyl car wrap and the car’s surface. Primer is a specialized coating that creates a smooth, even, and clean surface for the wrap to adhere to. By using primer, you can fill in tiny scratches and imperfections, creating a uniform surface that allows the adhesive to bond effectively. This, in turn, prevents peeling, lifting, and other common installation issues.

One of the key benefits of using primer is that it creates a chemical bond between the wrap and the surface. This bond is incredibly strong, allowing the wrap to withstand the elements and last for years to come. Additionally, primer helps to protect the car’s paint from damage, scratches, and fading. By using a high-quality primer, you can ensure that the car’s surface remains intact and undamaged, even after the wrap is removed.

In short, primer is an essential step in the surface preparation process. By taking the time to apply primer, you can ensure a strong and durable bond, prevent common installation issues, and protect the car’s paint. Whether you’re a seasoned installer or just starting out, using primer is a simple yet effective way to take your vinyl car wrap installations to the next level.

Common Surface Imperfections that Affect Adhesion

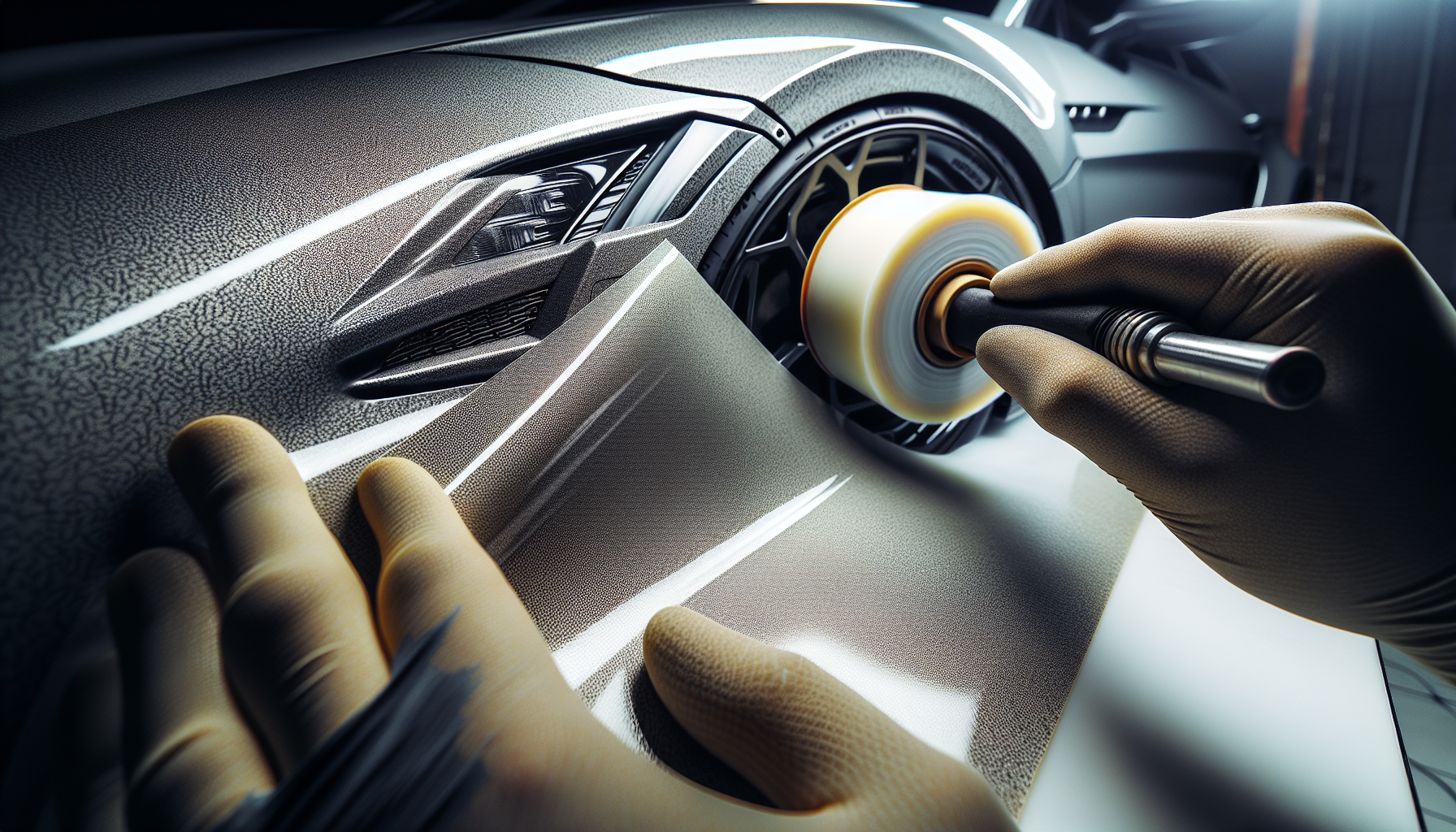

When it comes to vinyl car wrap installation, surface imperfections can be a major obstacle to achieving a strong and durable bond. Even tiny scratches, swirls, and contaminants can compromise the adhesion of the wrap, leading to peeling, lifting, and other installation issues. However, by identifying and addressing these common surface imperfections, you can ensure a smooth and successful installation.

Some of the most common surface imperfections that can affect adhesion include dirt, dust, and debris, as well as scratches, swirls, and oxidation. Additionally, paint defects, such as orange peel or fish eyes, can also compromise the bond between the wrap and the surface. By taking the time to inspect the surface and address these imperfections, you can create a smooth and even surface that allows the adhesive to bond effectively.

Fortunately, addressing surface imperfections is a relatively simple process. By using a combination of cleaning solutions, polishing compounds, and surface preparation tools, you can remove contaminants, fill in scratches, and smooth out the surface. By taking the time to prepare the surface, you can ensure a strong and durable bond that will last for years to come. Remember, a smooth surface is the key to a successful vinyl car wrap installation.

2. The Science Behind Vinyl Car Wrap Adhesion

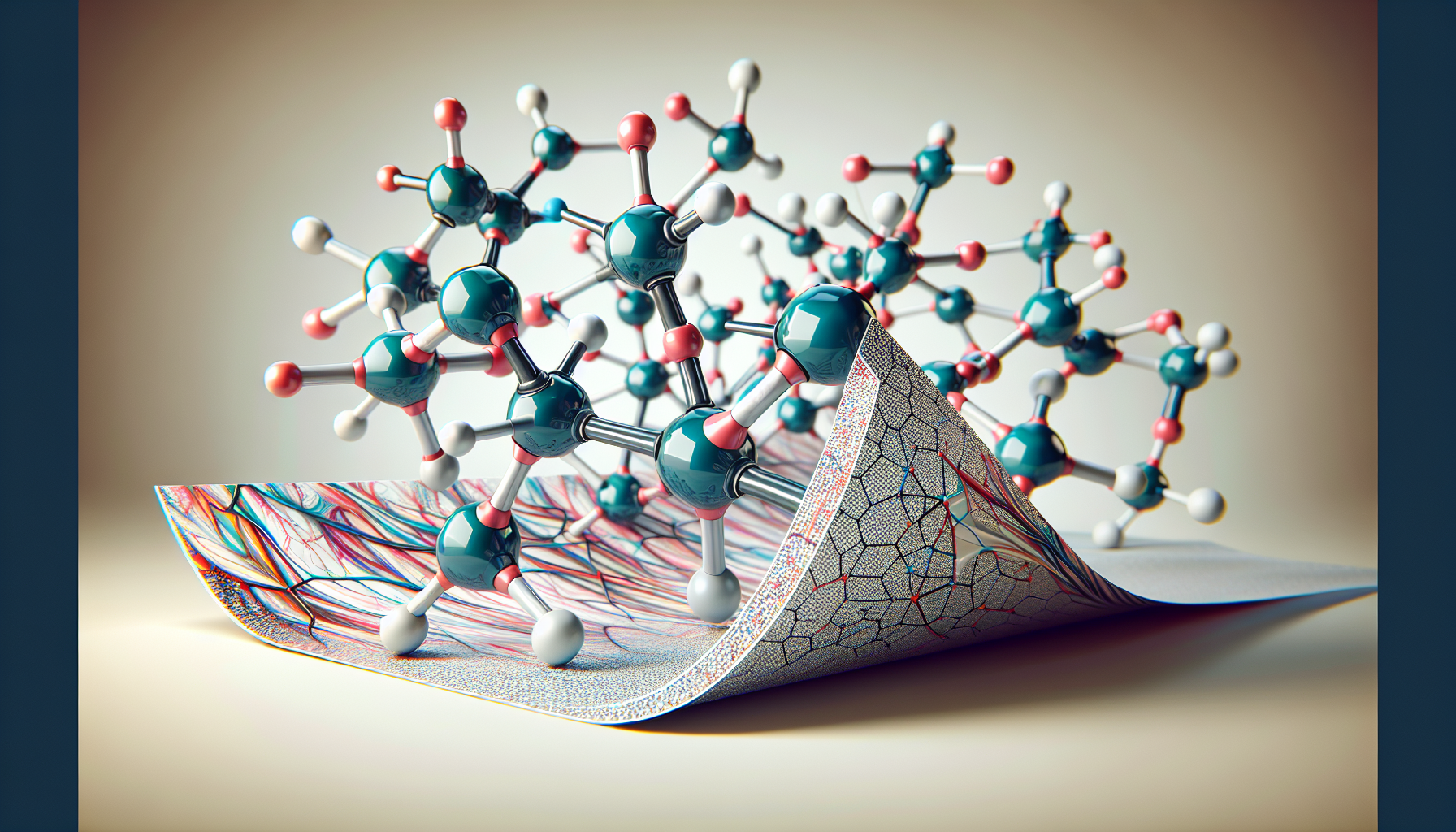

Adhesion is a complex science that involves the interaction of multiple forces and factors. When it comes to vinyl car wraps, understanding the science behind adhesion is crucial for achieving a strong and durable bond. At its core, adhesion is the process of creating a bond between two surfaces, in this case, the vinyl car wrap and the primer surface. This bond is created through a combination of mechanical and chemical forces, including van der Waals forces, electrostatic forces, and chemical bonds.

The type of adhesive used in vinyl car wraps plays a critical role in the adhesion process. Acrylic adhesives, for example, are commonly used in vinyl car wraps due to their excellent bonding properties. These adhesives work by creating a strong mechanical bond between the wrap and the surface, as well as a chemical bond that enhances the overall strength of the bond. Additionally, the surface energy of the primer surface also plays a critical role in the adhesion process, as it determines the ability of the adhesive to wet and bond to the surface.

By understanding the science behind adhesion, vinyl car wrap installers can optimize their installation techniques to achieve a strong and durable bond. This includes selecting the right adhesive for the job, preparing the surface properly, and applying the wrap under the right conditions. By taking the time to understand the science behind adhesion, installers can ensure a successful installation that will last for years to come.

The Role of Adhesives in Vinyl Car Wraps

Adhesives play a crucial role in the success of vinyl car wraps. They are responsible for creating a strong and durable bond between the wrap and the primer surface, ensuring that the wrap remains in place for years to come. There are several types of adhesives used in vinyl car wraps, each with its own unique characteristics and benefits. Acrylic adhesives, for example, are commonly used in vinyl car wraps due to their excellent bonding properties, flexibility, and resistance to UV light.

Another type of adhesive used in vinyl car wraps is solvent-based adhesives. These adhesives are known for their high bond strength and are often used in high-performance applications. However, they can be more difficult to apply and require special handling and disposal. Additionally, there are also specialized adhesives designed for specific surfaces, such as metal or glass. These adhesives are formulated to provide a strong bond on these surfaces, ensuring a durable and long-lasting finish.

When it comes to interacting with primer surfaces, adhesives play a critical role. The adhesive must be able to wet and bond to the surface, creating a strong mechanical bond. The primer surface must also be compatible with the adhesive, ensuring that the bond is strong and durable. By understanding the different types of adhesives used in vinyl car wraps and how they interact with primer surfaces, installers can select the right adhesive for the job and ensure a successful installation.

Factors that Affect Adhesion Strength

Adhesion strength is a critical factor in the success of vinyl car wraps. Several factors can influence the adhesion strength of vinyl car wraps, including temperature, humidity, and surface cleanliness. Temperature, for example, can affect the adhesive properties of the vinyl car wrap, with high temperatures potentially weakening the bond and low temperatures strengthening it. Humidity can also play a role, as high humidity can cause the adhesive to absorb moisture, leading to a weaker bond.

Surface cleanliness is also a critical factor in adhesion strength. A clean and smooth surface is essential for a strong bond, as any dirt, dust, or contaminants can weaken the adhesive properties of the vinyl car wrap. Additionally, the surface energy of the primer surface can also affect adhesion strength, as a high surface energy can enhance the bonding properties of the adhesive. By understanding the factors that influence adhesion strength, installers can take steps to optimize the installation process and ensure a strong and durable bond.

By controlling these factors, installers can ensure a successful installation that will last for years to come. This includes preparing the surface properly, selecting the right adhesive for the job, and applying the wrap under the right conditions. By taking the time to understand the factors that affect adhesion strength, installers can achieve a superior finish and ensure customer satisfaction.

3. Ensuring a Secure Bond Between Vinyl Car Wrap and Primer Surface

Ensuring a secure bond between the vinyl car wrap and primer surface is crucial for a successful installation. To achieve a strong and durable bond, it’s essential to follow expert tips and best practices. First, make sure the primer surface is clean and free of contaminants, as even the slightest imperfection can compromise the bond. Next, apply the correct amount of pressure when installing the wrap, as excessive pressure can cause the adhesive to stretch and weaken.

Another critical factor is the temperature and humidity levels during installation. Ensure the environment is within the recommended range for the specific adhesive and vinyl car wrap being used. Additionally, use a high-quality laminate to protect the wrap and enhance its durability. Finally, perform regular inspections and maintenance to detect any potential issues before they become major problems.

By following these expert tips, you can ensure a strong and durable bond between your vinyl car wrap and primer surface. Remember, a secure bond is essential for a successful installation that will last for years to come. With the right techniques and materials, you can achieve a professional-looking finish that will impress your customers and set your business apart from the competition.

Applying the Right Amount of Pressure

Applying the right amount of pressure is a critical step in the vinyl car wrap installation process. When installing a vinyl car wrap on a primer surface, it’s essential to apply the correct amount of pressure to ensure a strong and durable bond. Too little pressure, and the wrap may not adhere properly, leading to bubbles and peeling. On the other hand, too much pressure can cause the adhesive to stretch and weaken, compromising the bond.

The ideal pressure will depend on the specific vinyl car wrap and adhesive being used, as well as the surface temperature and humidity. Generally, a pressure of around 10-15 pounds per square inch (PSI) is recommended. However, it’s essential to consult the manufacturer’s guidelines and follow their recommended pressure settings. Additionally, using a high-quality squeegee or application tool can help ensure even pressure distribution and prevent air pockets from forming.

By applying the right amount of pressure, you can ensure a strong and durable bond between the vinyl car wrap and primer surface. This will help prevent common installation issues, such as bubbles and peeling, and ensure a professional-looking finish that will last for years to come. Remember, proper pressure application is key to a successful vinyl car wrap installation, so take the time to get it right and enjoy a flawless finish.

Using the Right Installation Tools and Techniques

When it comes to vinyl car wrap installation on a primer surface, having the right tools and techniques is crucial for a successful outcome. One of the most essential tools is a high-quality squeegee, which is used to apply even pressure and remove air bubbles from the wrap. A good squeegee should be flexible and have a soft, rubberized edge to prevent scratching the surface.

Another important tool is a heat gun or torch, which is used to stretch and conform the wrap to complex curves and surfaces. A heat gun can also be used to dry the adhesive and ensure a strong bond. Additionally, a good pair of scissors or a cutting tool is necessary for trimming the wrap to fit around edges and corners. Finally, a cleaning solution and microfiber cloth are essential for cleaning the surface and removing any dirt or debris.

By using the right installation tools and techniques, you can ensure a professional-looking finish and a successful installation. Remember, practice makes perfect, so don’t be afraid to experiment and refine your skills. With the right tools and techniques, you can achieve a flawless finish that will impress your customers and set your business apart from the competition. By following these tips and using the right tools, you can ensure a successful vinyl car wrap installation on a primer surface.

4. Conclusion: A Strong Bond for a Durable Finish

In conclusion, ensuring a secure bond between your vinyl car wrap and primer surface is crucial for a durable and long-lasting finish. By following the key takeaways from this article, you can ensure a successful installation that will impress your customers and set your business apart from the competition. From preparing the surface with a high-quality primer to applying the right amount of pressure and using the right installation tools and techniques, every step is critical in achieving a strong and durable bond.

By understanding the importance of surface preparation, the role of primer, and the factors that affect adhesion strength, you can take the necessary steps to ensure a successful installation. Additionally, by using the right installation tools and techniques, you can ensure a professional-looking finish that will last for years to come. Remember, a strong bond is the key to a durable finish, and with the right knowledge and skills, you can achieve a flawless finish that will exceed your customers’ expectations.

By following the tips and best practices outlined in this article, you can ensure a secure bond between your vinyl car wrap and primer surface, and achieve a durable and long-lasting finish that will make your car stand out from the crowd. With the right knowledge and skills, you can take your vinyl car wrap installations to the next level and deliver exceptional results that will make your customers proud to show off their vehicles.

Recap of the Importance of Surface Preparation

In order to achieve a successful vinyl car wrap installation, surface preparation is crucial. The surface of the car must be clean, dry, and free of contaminants, such as dust, dirt, and oils. This ensures that the adhesive can bond properly to the surface, creating a strong and durable finish. Additionally, any scratches or imperfections in the surface must be repaired and sanded to create a smooth finish.

A well-prepared surface also helps to prevent common installation issues, such as bubbles and peeling. By taking the time to properly prepare the surface, installers can ensure a professional-looking finish that will last for years to come. Furthermore, a well-prepared surface can help to reduce the risk of damage to the car’s paint, making it a crucial step in the installation process.

By following the surface preparation tips and best practices outlined in this article, installers can ensure a successful vinyl car wrap installation that will exceed their customers’ expectations. Remember, a well-prepared surface is the foundation of a successful installation, and by taking the time to get it right, installers can achieve a flawless finish that will make their customers proud to show off their vehicles.

Additional Resources for Vinyl Car Wrap Installers

As a vinyl car wrap installer, it’s essential to continuously improve your skills and knowledge to stay ahead of the competition. There are many external resources available that can help you further develop your skills and stay up-to-date with the latest techniques and trends.

One of the best resources is online tutorials and videos. Websites such as YouTube and Udemy offer a wide range of tutorials and courses on vinyl car wrap installation, covering topics such as surface preparation, application techniques, and troubleshooting common issues. Additionally, online forums and communities dedicated to vinyl car wrap installation can provide valuable insights and advice from experienced installers.

Another great resource is industry events and conferences. Attending events such as the SEMA Show or the ISA International Sign Expo can provide opportunities to network with other installers, learn about new products and technologies, and attend educational seminars and workshops. By taking advantage of these external resources, vinyl car wrap installers can further improve their skills and knowledge, and stay ahead of the competition in the industry.

What is the most important step in surface preparation for vinyl car wrap installation?

The most important step in surface preparation is to ensure the surface is clean and free of contaminants, such as dust, dirt, and oils. This will ensure a strong bond between the vinyl wrap and the surface.

How long does it take to install a vinyl car wrap?

The installation time can vary depending on the size and complexity of the design, but on average, it can take around 2-4 hours to install a full vinyl car wrap.

Can I install a vinyl car wrap myself?

While it’s possible to install a vinyl car wrap yourself, it’s recommended to have a professional installer with experience do it for you. This will ensure a high-quality finish and prevent any potential mistakes or errors.

How long does a vinyl car wrap last?

The lifespan of a vinyl car wrap can vary depending on factors such as weather conditions, driving habits, and maintenance. On average, a well-installed vinyl car wrap can last around 5-7 years.

Can I remove the vinyl car wrap myself?

It’s not recommended to remove a vinyl car wrap yourself, as it can cause damage to the car’s paint. Instead, have a professional installer remove it for you to ensure a safe and damage-free process.